Tecsystem introduces the new TRBH ventilation system for dry-type transformer temperature control. Tecsystem has been supplying temperature monitoring devices and temperature controls for transformers for more than 40 years, and utilizing this experience; the TRBH is designed to be the next evolution in transformer temperature control.

Transformers Cooling System: Precision and Efficiency

The TRBH system uses electronic, variable-speed fans to control the airflow across the coils precisely. The monitor used Pt100 RTD sensors to read the temperature at the hot spots of each transformer coil. As the temperature rises, the TRBH system sees the temperature rise and starts the cooling fans at reduced speeds before the set temperature is reached. This helps to reduce the thermal cycling of the coils, which can lead to resin cracking in a cast resin transformer over time.

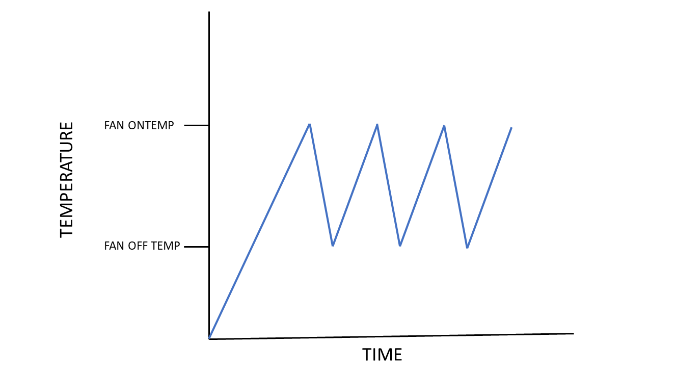

The graph below shows a typical temperature vs time graph using a single-speed fan and traditional temperature monitor on a transformer. As the temperature rises, the fans turn on at full speed at the “Fan ON Temp,” and the transformer is quickly cooled. Once the “Fan OFF” Temp is reached, the fans turn off, and the temperature of the transformer rises again quickly.

Revolutionary TRBH System: Smart Fan Technology for Optimal Temperature Control

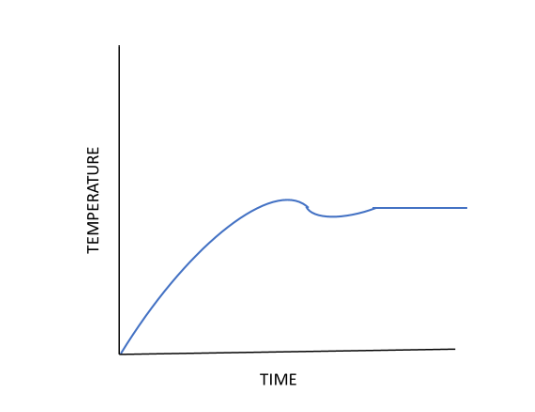

With the revolutionary TRBH system, the fans will come on at a slow speed before the programmed temperature is reached, slowing the rate of temperature rise. As the temperature rises, the fan will speed up until the temperature drops. Once this happens, the fans slow down to establish a near-steady state temperature condition over time.

Optimizing Transformer Cooling

Additionally, the fans are designed with transformers in mind. The squirrel cage fan’s low, wider profile can be sized to provide airflow across the coil, and the baffles on the fan outlet allow the air to be directed right where it is needed.

The reduced speed of the fans can save energy in operating the cooling system and reduce the fans’ noise level.

Each fan is monitored for overloads, and in case of a connection disruption, the fans will operate at 50% capacity while turning on a fault to alert maintenance of the problem. This helps prevent the transformer from overheating if there is a fan problem.

Each coil is monitored independently, allowing the fans only to be used where and when needed to prevent the transformer from overheating.

The TRBH temperature controller comes with either an Ethernet output (ETH) or RS485 output (Digital) and 4 inputs for Pt100 RTD sensors. This allows each coil to be monitored, and a 4th input is used to monitor the ambient conditions around the transformer, which can be used for room exhaust controls if necessary. The data outputs allow for high-level data collection. We believe you cannot control what you do not monitor. The revolutionary TRBH system from Tecsystem is the next step in transformer temperature monitoring. Contact us for more information.